H13 steel decorative aluminum extrusion profile mould

$100≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Guangzhou Port,Nansha Port,Shenzhen Port |

$100≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Guangzhou Port,Nansha Port,Shenzhen Port |

Place Of Origin: China

Forming Method: Extrusion Mould

Product Material: Steel

Advantages of aluminum alloy radiators:

At present, aluminum profile radiators are widely used in fields such as automobiles, electronic equipment, lighting equipment, etc.;

The aluminum radiator shell is one of the most important components of the radiator. Its main function is to protect the internal heat dissipation components and strengthen the structure of the entire radiator. Today I will take you to learn about the application of radiators and their shells.

Aluminum profiles are a common material for manufacturing radiator shells. They have the advantages of being lightweight, corrosion-resistant, and easy to maintain. In the processing and manufacturing process, stamping, hot pressing, processing, spraying and other technologies are usually used;

When designing an aluminum radiator shell, engineers usually consider the following aspects: shell size, cooling power, fan configuration, and installation method;

This can provide users with a more efficient, safe and reliable one-stop cooling solution.

Advantages of aluminum alloy radiator

1.Lightweight: Due to the lightweight characteristics of aluminum alloy materials, aluminum alloy radiators are lighter than traditional copper radiators, which can reduce the overall weight of mechanical equipment.

2.Good corrosion resistance: Aluminum alloy radiators have excellent oxidation resistance and anti-corrosion properties, and are not prone to rust or oxidation problems after long-term use.

3.Simple manufacturing process: The manufacturing process of aluminum alloy radiators is relatively simple, the production cost is low, and large quantities of products can be produced more cheaply.

Up till now, JIELIWEI has been keeping a wonderful cooperative relationship with more than 100 domestic and oversea customers. Most of our clients chose us because of our precision design, fast production, competitive price, and professional service.

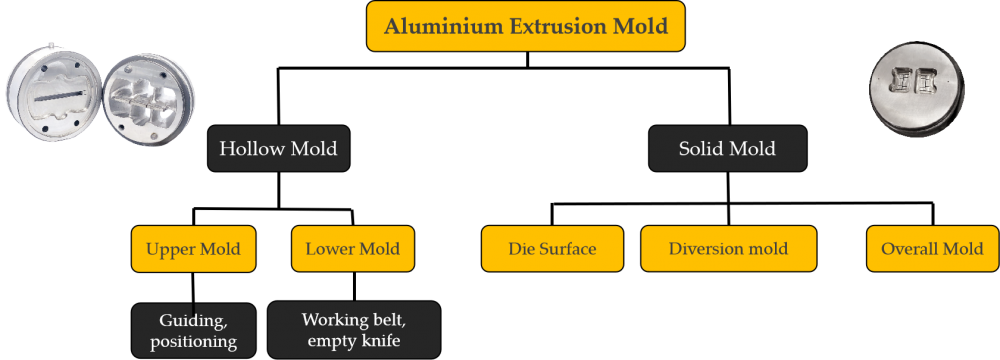

The Difference Between Solid Die and Hollow Die Solid Die The solid die is relatively simple, as long as the split hole is designed, the aluminum handle is squeezed out of the flat flag hole to form a cross section after mixing. Like aluminum flat strips, aluminum rods, some special-shaped materials, etc. Hollow Die Hollow dies are generally combined by two combined molds, so that the cavity can be formed by splitting the flow through the working belt during extrusion, such as aluminum shells and round tubes. For ordinary extrusion dies, to produce hollow profiles, a splitter die must be used, which consists of an upper die and a lower die. The upper die is generally used to guide flow and position the hollow part of the hollow profile. The lower mold is the outer surface working belt and empty knife. Most of the non-hollow profiles use solid dies. Generally speaking, there is only one mold including diversion and working belts. Of course, there are special cases. Here we only explain the general production conditions.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.