Customized aluminium extrusion molds for LED panel Light

$100≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Guangzhou Port , Nansha Port ,Shenzhen Port |

$100≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Guangzhou Port , Nansha Port ,Shenzhen Port |

Place Of Origin: China

Forming Method: Extrusion Mould

Product Material: Steel

Advantages of Aluminum Extrusion Dies

1. The extrusion method can not only produce rods, pipes and other products with simple cross-sectional shapes, but also hollow and solid products with complex cross-sectional shapes.

2. The production flexibility of the extrusion method is very large. Products with different shapes and sizes can be produced only by changing the mold. The mold replacement time is short and the production efficiency is high, which is of great significance for the production scale of small batches.

3. The dimensional accuracy of extruded products is far better than that of rolling and die forging, and the surface roughness is better, so it can be processed without processing and become a finished product.

4. The mechanical properties of extrusion products are good, especially for aluminum and aluminum alloy products, the extrusion effect is that after quenching or aging, the longitudinal properties of the products are higher than those of rolling and die forging.

5. Compared with rolling, extrusion equipment has compact structure, less land occupation, less infrastructure cost, simple operation and easy maintenance.

6. It is easy to realize semi-automation or automation.

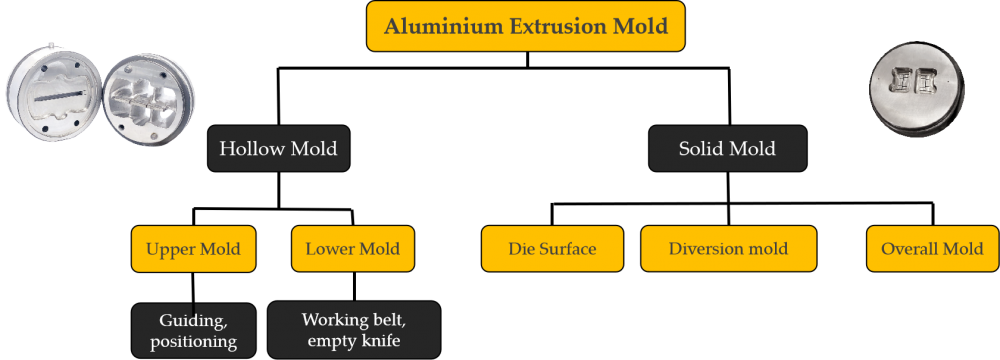

The Difference Between Solid Die and Hollow Die

Solid Die

The solid die is relatively simple, as long as the split hole is designed, the aluminum handle is squeezed out of the flat flag hole to form a cross section after mixing.

Like aluminum flat strips, aluminum rods, some special-shaped materials, etc.

Hollow Die

Hollow dies are generally combined by two combined molds, so that the cavity can be formed by splitting the flow through the working belt during extrusion, such as aluminum shells and round tubes.

For ordinary extrusion dies, to produce hollow profiles, a splitter die must be used, which consists of an upper die and a lower die. The upper die is generally used to guide flow and position the hollow part of the hollow profile. The lower mold is the outer surface working belt and empty knife.

Most of the non-hollow profiles use solid dies. Generally speaking, there is only one mold including diversion and working belts. Of course, there are special cases. Here we only explain the general production conditions.

If you are looking for Architectural aluminum profile mold, Decorative Aluminum Profile Mold, Industrial Aluminum Profile Molds and Furniture Aluminum Profile Mold, we are the perfect Aluminium Extrusion Mould manufacturer from China for you.

Aluminum profiles are widely used in homes.

Here are some common applications:

1. Window and door frames: Aluminum profiles are widely used to make window and door frames because they have good corrosion resistance, are not easily deformed, and have low maintenance costs.

2. Furniture: Many modern furniture, such as tables, chairs and bed frames, are made of aluminum profiles. They are lightweight and durable, can hold weight, and can be made in a variety of shapes and styles.

3.Kitchen equipment: Aluminum profiles are also commonly used to make kitchen equipment, such as cabinets, range hoods, etc. They are heat and moisture resistant, making them ideal for kitchen environments.

4. Decorative materials: Aluminum profiles are also commonly used in interior decoration, such as ceilings, sidings, floors, etc. They have a good decorative effect and can enhance the overall beauty of the interior.

5. Balcony railings: Aluminum profiles are also often used to make balcony railings because they are resistant to wind and sun and are not prone to rust and deformation.

6. Bathroom equipment: In the bathroom, aluminum profiles can be used to make shower room frames, bathroom cabinets, etc.

Generally speaking, aluminum profiles are widely used in homes. They are both practical and beautiful and are an indispensable part of home design.

Introduction to H13 mold steel H13 mold steel is a hot work mold steel with good thermal strength and hot hardness, good wear resistance and fatigue resistance, good thermal creep resistance, and high hardness after heat treatment, which can reach HRC46-50. H13 mold steel has stable chemical composition, excellent impact toughness and high toughness, which can ensure the service life of the mold. H13 die steel is mainly used to manufacture high-strength hot tools, such as hot extrusion dies, hot forging dies, die-casting dies, hot shear blades, etc. In addition, it can also be used to manufacture large plastic molds, cold stamping molds, etc. The advantage of H13 mold steel is that it has high heat resistance and wear resistance, as well as good oxidation resistance and thermal fatigue resistance, and can maintain good hardness and wear resistance at high temperatures. However, H13 mold steel has poor welding performance and requires special welding processes.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.