decorated sanitary ware aluminum profile extrusion dies

$100≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Guangzhou Port,Nansha Port,Shenzhen Port |

$100≥1Set/Sets

| Payment Type: | L/C,T/T |

| Incoterm: | FOB,EXW |

| Min. Order: | 1 Set/Sets |

| Transportation: | Ocean |

| Port: | Guangzhou Port,Nansha Port,Shenzhen Port |

Place Of Origin: China

Forming Method: Extrusion Mould

Product Material: Steel

Aluminum alloy sanitary ware refers to products made of aluminum alloy materials in sanitary products. Aluminum alloy is a metal material with the characteristics of light weight, high strength and good corrosion resistance, so it is widely used in sanitary products.

Aluminum alloy sanitary products include shower rooms, bathtubs, wash basins, toilet accessories, etc. These products usually use aluminum alloy frames, combined with other materials such as glass, ceramics, etc., to achieve beautiful and practical designs.

Aluminum alloy sanitary products have the following advantages:

1. Lightweight: Aluminum alloy materials are relatively light, making sanitary products easier to install and transport.

2. High strength: Aluminum alloy has high strength and can provide solid support and durability.

3. Good corrosion resistance: Aluminum alloy has good corrosion resistance and can resist the erosion of sanitary products by water vapor, humidity and other environments.

4. Easy to clean: The aluminum alloy surface is smooth and not easy to accumulate dirt, making it more convenient to use.

5. Beautiful appearance: Aluminum alloy sanitary products usually adopt modern designs and diverse color choices, which can meet the aesthetic needs of different consumers.

In short, aluminum alloy sanitary ware products have become a popular product in the sanitary ware market due to their lightweight, high strength, and good corrosion resistance. They not only provide a comfortable use experience, but also add a sense of modernity and style to the sanitary space.

JIELIWEI has been providing Aluminium Profile mould for clients at home and abroad. With extraordinary craftsmanship and competitive price in this trade, more and more clients established long-term cooperative relationships with us.

If you are looking for Architectural Aluminum Profile Mold, Decorative Aluminum Profile Mold, Industrial Aluminum Profile Molds, Curtain Wall Aluminium Profile Extrusion Dies, Lighting Material Aluminium Profile Extrusion Dies, Roller Shutter Aluminium Profile Extrusion Dies..., Jieliwei is the perfect extrusion mold supplier for you!

Introduction to H13 mold steel

H13 mold steel is a hot work mold steel with good thermal strength and hot hardness, good wear resistance and fatigue resistance, good thermal creep resistance, and high hardness after heat treatment, which can reach HRC46-50. H13 mold steel has stable chemical composition, excellent impact toughness and high toughness, which can ensure the service life of the mold.

H13 die steel is mainly used to manufacture high-strength hot tools, such as hot extrusion dies, hot forging dies, die-casting dies, hot shear blades, etc. In addition, it can also be used to manufacture large plastic molds, cold stamping molds, etc.

The advantage of H13 mold steel is that it has high heat resistance and wear resistance, as well as good oxidation resistance and thermal fatigue resistance, and can maintain good hardness and wear resistance at high temperatures. However, H13 mold steel has poor welding performance and requires special welding processes.

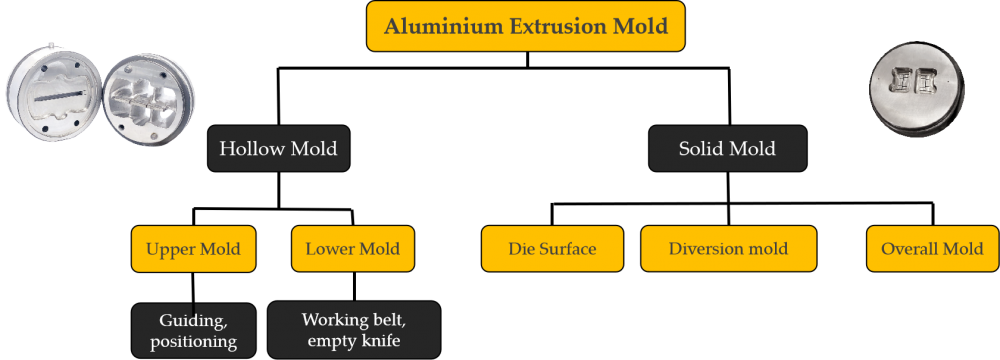

The Difference Between Solid Die and Hollow Die

Solid Die

The solid die is relatively simple, as long as the split hole is designed, the aluminum handle is squeezed out of the flat flag hole to form a cross section after mixing.

Like aluminum flat strips, aluminum rods, some special-shaped materials, etc.

Hollow Die

Hollow dies are generally combined by two combined molds, so that the cavity can be formed by splitting the flow through the working belt during extrusion, such as aluminum shells and round tubes.

For ordinary extrusion dies, to produce hollow profiles, a splitter die must be used, which consists of an upper die and a lower die. The upper die is generally used to guide flow and position the hollow part of the hollow profile. The lower mold is the outer surface working belt and empty knife.

Most of the non-hollow profiles use solid dies. Generally speaking, there is only one mold including diversion and working belts. Of course, there are special cases. Here we only explain the general production conditions.

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.

Fill in more information so that we can get in touch with you faster

Privacy statement: Your privacy is very important to Us. Our company promises not to disclose your personal information to any external company with out your explicit permission.